What Can Configure-Price-Quote Do For Your Manufacturing Organization?

A5 is the leader in CPQ implementations with over 15+ years experience and brings a unique perspective and point of view to the Manufacturing sector to optimize, enhance and extend the sales platform using CPQ, bringing speed to market and value to their customers.

Below we will walk you through the fundamentals of CPQ including:

How do you optimize your end-to-end Manufacturing using a rightly designed Configure-Price-Quote functionality?

Which of your Manufacturing processes should you transform?

How do you achieve the highest quality with Superior Customer Satisfaction with great margins?

How do you choose a systems integrator, knowledgeable in manufacturing, that can help design, architect and implement what you need?

In today’s competitive business environment, customers are demanding products and services tailored to their unique specifications, expect companies to provide customized versions of products on demand and ship them to/from anywhere in the world. Enterprises must be agile, quickly bringing new products to market, responding to changing demand and delivering high-quality products at a reasonable price to stay competitive in the marketplace.

An integrated CPQ to ERP solution empowers the enterprise to thrive in this environment by providing a comprehensive, tailored solution for any engineer-to-order, build-to-order, assemble-to-order, and purchase-to-order environment. Sales representatives or customers themselves can quickly record customer requirements over the Internet and tailor complex product and service configurations to meet those needs. A robust CPQ solution can streamline configuration management and deploy an efficient build-or-purchase-to-customer-demand solution with the shortest possible fulfillment cycle times.

CPQ is a required tool for every organization selling complex products. In the front office, CPQ helps the sales team create accurate and quick quotes, dramatically reducing the sales cycle. It can be used as a weapon to stay competitive.

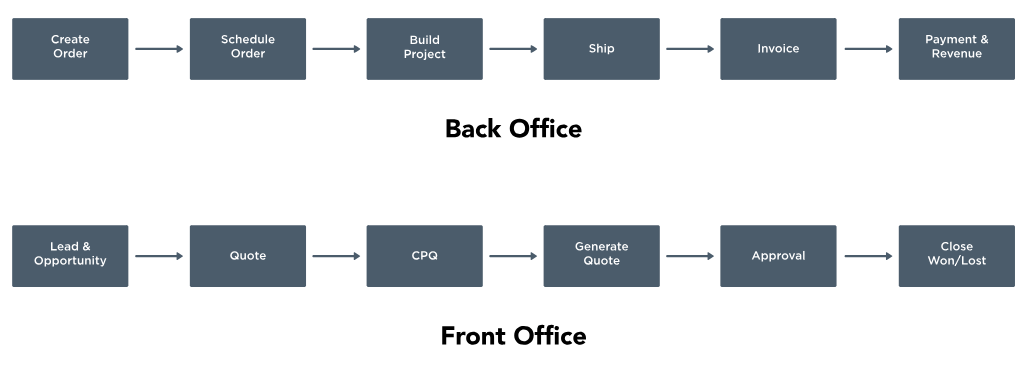

Back office solutions, like ERP (Enterprise Resource Planning) and Supply Chain Planning, are the backbone of their entire operations. When a business manufactures complex products with many options, a robust CPQ solution ensures every order is feasible and adheres to engineering rules. To ensure CPQ benefits are passed to the back office, the right integration to the back office is necessary. What Sales “want” from CPQ and what Manufacturing operations “need” to successfully deliver a product may be two different things, but using the right integration they both can benefit from a robust CPQ solution. In other words, the right alignment between Front Office and Back Office is essential for any organization to benefit from its CPQ investment.

Front-office and Back-office solutions manage different processes and have different transactional data with multiple integration points. Master Data and Business Logic need to be replicated in both systems. In an ideal situation, you need to define one system as a (single) source of truth and build the right integration around it. If you already have back-end ERP functional, which is the case for large manufacturers, the ERP system becomes a system of record and CPQ/CRM needs to interface.

Front-office and Back-office solutions manage different processes and have different transactional data with multiple integration points. Master Data and Business Logic need to be replicated in both systems. In an ideal situation, you need to define one system as a (single) source of truth and build the right integration around it. If you already have back-end ERP functional, which is the case for large manufacturers, the ERP system becomes a system of record and CPQ/CRM needs to interface.

In a complex sales cycle, when an opportunity is in the advance stage and the probability of winning is higher, the back office should know what is coming, particularly for long lead time products. When there are thousands of quotes worked on across multiple sales cycles, this advanced knowledge helps the Supply Chain team to optimize inventory and production planning to plan better. Product schedulers can look into the current assembly line and procurement can optimize inventory levels.

Apart from master data, most CPQ solutions involve intangible data like color, size, etc. which are specific to Customers’ products and processes. These data elements are set up as Attributes in CPQ. The Attribute value is captured in runtime either by the user manually selecting or calculated by complex formulas. For back-end supply chain planning and ERP systems, this information is equally important in forecasting & planning, shipping & shipping documentation, and during the build.

Typically Manufacturing BOMs are huge with 1000’s components in multi-level BOMs. These BOMs are set up as ATO (Assemble-To-Order), PTO (Pick-To-Order), or CTO (Configure-To-Order) configurations. ATO BOMs have routing associated with them. Depending on it is traditional or lean manufacturing, there may be one or more work orders. Along with material cost, resource cost, overhead, and other costs are rolled up to the higher level assembly to get accurate cost.

Design to Release Process

The product management team which is involved in creating and maintaining product models in a Product Lifecycle Management (PLM) application should incorporate which product models/bundles will be available in which markets. They should build the basic building blocks in terms of product attributes and rules which govern how different options will be packaged and offered together or separately. PLM being the source of truth should then pass on this information to CPQ, so that it can then leverage it to build configuration and quoting rules which control product availability, compatibility and ability to fulfill for different customers.

While importing these products and services, it is necessary to account for different product definitions such as: Pick to Order (PTO), Assemble to Order (ATO), Configure To Order (CTO), Engineer To Order (ETO), Finished goods/standalone products, bundles, Kits, and Services. It is important to do so to ensure valid configurations and orders, ability to build, ship and invoice.

These definitions also include specifying discrete and flow routings (if applicable), lead times, and costs that are then used in downstream processing to create unique configuration item routings, and calculate lead times, and costs.

Workflow Enabled Order Fulfillment

Whether CPQ is integrated with eCommerce or used internally by Sales reps, it is important for the front office to know the status of Orders. Once the customer accepts Quote and Order is created, through integration, the order is pushed to Order Management in ERP. Now the order in ERP goes through various stages. The order can be put in entered status, scheduled to build or waiting on long lead time parts required for assembly. Again, with proper integration, Front Office can be updated with the status of the order in Manufacturing and expected ship date.

Integration with Order Management (OM) allows CPQ Cloud sales users to create, update, and cancel orders in ERP OM through the CPQ Cloud user interface. After relevant products have been added to a Transaction and approvals have been obtained, the CPQ Cloud sales user can:

- Create Order – Creates an order in OM using the CPQ Cloud Transaction data

- Update Order – Updates an existing OM order if Transaction details have changed

- Cancel Order – Cancels an existing OM order

- Cancel Line – Cancels any line that is selected from an existing OM order

Different Types of Product Types which need to be accounted for:

PTO Models: CPQ – Sales order integration must take into account that a configured model created in CPQ will result in separate “shippable” components in ERP which could be grouped by “SHIP SET” or shipped to separate addresses. CPQ rules must not violate BOM Rules Established in ERP.

ATO Models: CPQ – Sales order interface must take into account that a configured model created in CPQ will result in a top-level assembled product in EBS, which will create “configured product identification assemblies” and possibly “work in progress” (WIP) discrete work orders for the sub-assemblies.

CTO Models: It is a combination of parent PTO/ATO model with one or more ATO models or nested ATO models as sub-assemblies. CPQ – Sales order integration must account for such complex configuration structures. Such a configured model in CPQ will result in the assembled product(s) in EBS, which will create “configured product identification assemblies” and possibly “work in progress” (WIP) discrete work orders for the sub-assemblies. Additionally, it may create “Shippable” components in ERP to group assembled and purchased products together.

ETO Models: They are custom solutions built as per customer specifications. It is a product which has never been engineered before, the costs and lead times are unknown, and detailed product data about the solution, such as performance data and drawings, are unknown. By leveraging CPQ configuration attributes and workflows such custom requirements are routed through automatically through various business functions such as engineering, manufacturing, procurement, sales, and service to provide a timely quote to the customer which if ordered can then be manufactured and fulfilled.

Inventory On Hand Balance

Accurate and Real-Time Capable to Promise

CPQ should integrate with Order Management and Planning and Scheduling to provide sophisticated, fast, accurate, and flexible order promising for PTO and ATO orders – including multilevel global supply chain Available to Promise (ATP), Capable to Promise (CTP), and Capable to Deliver (CTD). Model configurations can be sourced from one or many internal or external facilities and can be restricted based on the specific options chosen by the customer. After product options are selected and by leveraging configuration attributes a web-service call can be made to global order promising first to check to see if the ordered configuration matches an existing configuration in the system. If it does, it performs capably to promise checks to choose the best source and get an estimated product availability date based on the matching configurations supply and capacity. If no match is found, or no supplies exist for the matched item, capable to promise checks are performed off the model and options selected. This gives customers the flexibility to pre-build popular configurations, or use up excess inventory caused by previous order cancellations. This also helps with inventory optimization as an organization can satisfy new sales order demand with existing inventory and reduce excess inventory by reserving matched configurations.

Material Reservation and Parts

Integration with Material Reservation allows CPQ sales users to perform the material reservation functionality. Once an order is created, line items can be reserved by invoking reserve action in ERP. Upon cancellation of an entire order or of one or more line items, the relieve line actions can be performed to relieve the reservation done against the order or line items, respectively.

Forecasting

A global forecast can be created to create a single, consolidated view of an organization’s global demand for sourced configurations, which can then be allocated to specific shipping organizations. Orders placed from CPQ lead to sales order demand for configurations which automatically consume forecasts for models, option classes, options, and mandatory components.

Flow Manufacturing for Configurations

Flow manufacturing is a “pull” based system that manufactures to customer demand by enabling mixed model production on balanced assembly lines. For example, oil and gas, food, and pharmaceutical industries are based on flow manufacturing. It utilizes sequenced schedules instead of work orders to drive production. Configuration and quote level information from CPQ helps to build assemble to order items and configurations with the highest efficiency and the shortest possible manufacturing cycle time.

“Operators on the shop floor can use the Flow Workstation to see the details of the flow schedule and the configuration, enabling a ‘paperless’ shop floor, even for complex configurations.”

Workflow enabled order fulfillment automatically progresses a customer order from booking to production schedules. After the configuration item, bill of material and flow routing is created, a flow schedule can be automatically generated, or it can be sequenced along with other orders using Flow’s advanced sequencing engine. Information from CPQ in many cases helps to build dynamic routing.

Sub-assembly configurations can be sequenced to the parent line using feeder line synchronization, or to customers supplier using outbound sequencing. Operators on the shop floor can use the Flow Workstation to see the details of the flow schedule and the configuration, enabling a “paperless” shop floor, even for complex configurations. When schedules are completed using Flow Manufacturing’s work order-less completion, all components and resources are back-flushed and the assembly is automatically reserved to satisfy a specific sales order.

Discrete Manufacturing for Configurations

In case of discrete manufacturing, orders placed from CPQ would leverage workflow enabled order fulfillment process in an ERP application to automatically open and reserve a manufacturing work order to assemble unique configurations from components based on the configured sales order. Most automotive, industrial equipment and hi-tech industries use discrete manufacturing.

Configuration and quote level information is passed downstream to assist in the creation of work orders, routing and manufacturing components as per customer specifications. Sub-assembly work orders, flow schedules, internal requisitions or purchase orders can also be automatically created as part of this process. During the configuration process in CPQ, relevant customer selections can be passed to third party drawing applications like AutoCAD, PRO-E to generate assembly drawings. These drawings are then passed to ERP as order attachments and finally get attached to word orders.

As work orders move through the routing, components are issued to the work orders, and resource and manufacturing overhead are charged. Inventory is automatically reserved for the sales order upon completion of the work order. Operators on the shop floor can use the Manufacturing Execution System for Discrete to see a dispatch list of all configurations they need to build, drill down to the components and work instructions required to build the configuration, clock in and clock out to record actual time, and record exceptions enabling a “paperless” shop floor, even for complex configurations. Production Scheduling provides a state-of-the-art production scheduling system that improves resource utilization and order fill rates while increasing the working efficiency of the scheduler.

The above whitepaper highlights A5’s experience in architecting and delivering lead-to-cash solutions for the manufacturing industry for 15+ years. Along with our vast pool of certified and talented resources, we leverage our proprietary IPs such as Automated Testing Suite: CPQ Spydr and A5 Agile Hybrid Implementation Methodology to deliver quality solutions.

A5 guides businesses through their Digital Transformation journey with a focus on Campaign-to-Cash. As leading solutions providers and systems implementers, we modernize your business processes through our strategic methodology using industry-leading platforms.